In the realm of automotive detailing, ceramic coatings have emerged as a revolutionary solution for protecting vehicle exteriors. Offering unparalleled durability and a mesmerizing shine, ceramic coatings have swiftly become a favorite among car enthusiasts and professionals alike. But what exactly makes ceramic coatings so durable? Delving into the intricate science behind this cutting-edge technology unveils a fascinating tale of molecular bonding and surface chemistry.

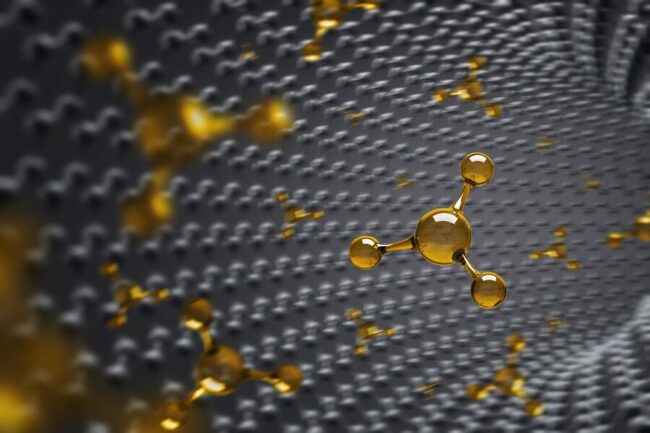

Ceramic coatings, also known as nanocoatings, are nano-sized particles that form a protective layer when applied to the surface of a vehicle. This layer chemically bonds with the paint, creating a shield that is resistant to various environmental contaminants such as dirt, water, UV rays, and chemical pollutants. The result is a glossy finish that not only enhances the aesthetic appeal of the vehicle but also provides long-lasting protection against wear and tear.

To understand the durability of ceramic coatings, it is essential to examine the composition of these coatings at the molecular level. Most ceramic coatings are based on silicon dioxide (SiO2), which is a compound known for its exceptional hardness and heat resistance. When applied to the surface of a vehicle, the SiO2 nanoparticles penetrate the microscopic pores of the paint, forming a strong bond that is resistant to degradation.

Molecular Bonding: The Foundation

The durability of ceramic coatings is rooted in the fundamental concept of molecular bonding. Upon application to a vehicle’s surface, the nanoparticles present in the ceramic coating initiate a robust chemical bonding process with the underlying paint. This bonding is pivotal, as it guarantees a snug adherence of the protective layer to the surface, thus creating a continuous barrier against environmental aggressors. Through the molecular bonding established between the ceramic coating and the paint, a resilient shield forms, impervious to degradation.

This ensures enduring protection for the vehicle’s exterior, preserving its aesthetic appeal and integrity over an extended period. The tight molecular bond acts as a safeguard against wear and tear, making ceramic coatings an indispensable solution for maintaining the pristine condition of vehicles amidst various environmental challenges.

SiO2 Nanoparticles: Key Players

SiO2 nanoparticles, as the primary constituents of ceramic coatings, are essential for enhancing durability due to their remarkable properties. Silicon dioxide, or silica, is recognized for its hardness and resistance to heat, making it an optimal choice for automotive protection. When these nanoparticles are applied to a vehicle’s surface, they infiltrate the microscopic pores of the paint, establishing a robust bond that withstands wear and tear.

SiO2 nanoparticles, as the primary constituents of ceramic coatings, are essential for enhancing durability due to their remarkable properties. Silicon dioxide, or silica, is recognized for its hardness and resistance to heat, making it an optimal choice for automotive protection. When these nanoparticles are applied to a vehicle’s surface, they infiltrate the microscopic pores of the paint, establishing a robust bond that withstands wear and tear.

Acting as a protective barrier, they effectively shield the vehicle’s exterior from various environmental factors including harmful UV rays, dirt, and chemical pollutants. This molecular-level fortification ensures that the vehicle maintains its pristine appearance while prolonging its lifespan, making ceramic coatings an indispensable investment for automotive enthusiasts.

Curing Process: Strengthening Bonds

The curing process plays a pivotal role in fortifying the durability of ceramic coatings. Following application, ceramic coatings undergo a transformative curing phase, during which cross-links form among the nanoparticles within the coating. These cross-links create a robust network, bolstering the bonds between nanoparticles and fortifying the protective layer. Consequently, the ceramic coating exhibits heightened resistance against abrasions, chemical deterioration, and environmental wear.

This process ensures the vehicle’s exterior remains shielded and retains its lustrous finish for an extended duration. By undergoing this curing process, ceramic coatings not only enhance their resilience but also significantly prolong the lifespan of the protective barrier, offering superior protection against the rigors of daily use and environmental exposure.

Cross-Link Formation: Enhancing Resilience

Cross-link formation is a key mechanism through which ceramic coatings achieve enhanced resilience. During the curing process, the SiO2 nanoparticles within the coating form cross-links with one another, creating a three-dimensional network structure. This network enhances the resilience of the ceramic coating, making it more resistant to scratches, abrasion, and chemical damage.

By strengthening the bonds between the nanoparticles, cross-link formation ensures that the protective layer remains intact even in the face of harsh environmental conditions, providing long-lasting protection for the vehicle’s exterior.

Hydrophobic Properties: Water Repellency

The hydrophobic properties of ceramic coatings are a cornerstone of their durability, offering remarkable benefits for vehicle protection. By repelling water, ceramic coatings create a shield that prevents moisture from settling on the vehicle’s surface. This not only simplifies cleaning routines but also minimizes the risk of water-induced damage, such as rust and corrosion.

By effectively repelling water, ceramic coatings uphold the integrity of the protective layer, ensuring prolonged protection for the vehicle’s exterior. Additionally, this hydrophobic barrier contributes to the maintenance of a glossy finish over time, enhancing the aesthetic appeal of the vehicle. With ceramic coatings, drivers can enjoy the peace of mind that comes with superior protection against environmental elements, all while maintaining a stunning appearance that lasts.

Environmental Contaminants: Repulsion Mechanisms

Ceramic coatings are designed to repel a wide range of environmental contaminants, including dirt, dust, pollen, bird droppings, and tree sap. The protective layer formed by ceramic coatings creates a barrier that prevents these contaminants from adhering to the surface of the vehicle.

Additionally, the hydrophobic properties of ceramic coatings make it easier to wash away contaminants that do come into contact with the surface, reducing the risk of scratches and swirl marks during the cleaning process. By repelling environmental contaminants, ceramic coatings help to preserve the pristine appearance of the vehicle and ensure long-lasting protection for its exterior.

Chemical Composition: SiO2 Insights

The chemical composition of ceramic coatings, particularly the presence of silicon dioxide (SiO2) nanoparticles, plays a crucial role in determining their durability. Silicon dioxide is known for its exceptional hardness and heat resistance, making it an ideal material for automotive protection.

When applied to the surface of a vehicle, SiO2 nanoparticles penetrate the microscopic pores of the paint, forming a strong bond that is resistant to wear and tear. This chemical bonding ensures that the ceramic coating remains intact even in the face of harsh environmental conditions, providing long-lasting protection for the vehicle’s exterior.

Surface Chemistry: Molecular Interactions

The durability of ceramic coatings hinges upon the intricate dance of molecular interactions occurring at the surface of the vehicle. As ceramic coatings are meticulously applied, the nanoparticles woven within the coating forge robust chemical bonds with the underlying paint, establishing a resilient shield against degradation. Furthermore, during the curing process, cross-link formation between the nanoparticles occurs, fortifying the coating’s structure and bolstering its durability.

These molecular interactions collectively weave a protective barrier, safeguarding the vehicle’s exterior from the onslaught of environmental contaminants. With this shield in place, the vehicle remains shielded, retaining its glossy finish and pristine appearance for an extended period. It’s this intricate web of molecular interactions that ensures ceramic coatings deliver unparalleled protection, preserving the beauty and integrity of your vehicle for years to come.

Longevity Assurance: Durability Factors

Several factors contribute to the longevity and durability of ceramic coatings, ensuring that they provide long-lasting protection for the vehicle’s exterior. The chemical composition of ceramic coatings, particularly the presence of silicon dioxide nanoparticles, plays a crucial role in enhancing durability. Additionally, the curing process strengthens the bonds between the nanoparticles, creating a resilient barrier that is resistant to wear and tear.

Several factors contribute to the longevity and durability of ceramic coatings, ensuring that they provide long-lasting protection for the vehicle’s exterior. The chemical composition of ceramic coatings, particularly the presence of silicon dioxide nanoparticles, plays a crucial role in enhancing durability. Additionally, the curing process strengthens the bonds between the nanoparticles, creating a resilient barrier that is resistant to wear and tear.

Furthermore, the hydrophobic properties of ceramic coatings repel water and prevent environmental contaminants from adhering to the surface of the vehicle. By combining these durability factors, ceramic coatings ensure that the vehicle remains protected and maintains its pristine appearance for an extended period.

Protective Barrier: Shielding Mechanisms

Ceramic coatings act as an impenetrable shield, safeguarding the vehicle’s surface from an array of environmental hazards. The presence of silicon dioxide nanoparticles within the coating forms a robust bond with the paint, ensuring the protective layer’s resilience against harsh conditions. This chemical composition fortifies the coating, maintaining its integrity even in the face of relentless exposure to UV rays, pollutants, and abrasive materials.

Moreover, the hydrophobic nature of ceramic coatings repels water effectively, thwarting its ability to cling onto the vehicle’s surface. By preventing water retention, ceramic coatings mitigate the risks of water-induced damage, such as corrosion and rust formation. Through the synergistic combination of these protective mechanisms, ceramic coatings offer unparalleled defense, preserving the vehicle’s aesthetic appeal and glossy finish for an extended duration. Invest in the long-term protection of your vehicle with Ceramic Garage’s expertise in harnessing advanced ceramic coating technology.

In conclusion, the science behind ceramic coating durability unveils a fascinating tale of molecular bonding, surface chemistry, and protective mechanisms. From SiO2 nanoparticles forming strong bonds with the paint to the hydrophobic properties repelling water and contaminants, ceramic coatings offer unparalleled protection for your vehicle’s exterior. By understanding the intricate processes at play, we can appreciate the resilience and longevity that ceramic coatings provide, ensuring that your vehicle remains pristine and glossy for years to come.

Experience the ultimate protection for your vehicle with Ceramic Garage. Our team is dedicated to harnessing cutting-edge technology to safeguard and enhance your vehicle’s aesthetics. Contact us today at (209) 780-7170 or email us at [email protected] to schedule your ceramic coating service and discover the difference for yourself. Don’t settle for anything less than the best – protect your investment with Ceramic Garage.