When summer hits and temperatures soar, keeping cool becomes a top priority. Whether you’re dealing with a hot car exterior, trying to keep your home comfortable, or protecting industrial equipment from heat damage, heat-resistant ceramic coatings offer a powerful solution. These coatings are designed to withstand high temperatures, shielding surfaces from the sun’s intense rays and helping to manage heat in various applications.

Why Heat-Resistant Ceramic Coatings Matter

Think about those scorching days when you step into your car and the dashboard feels like a frying pan. Heat-resistant ceramic coatings can help make this a thing of the past. By applying a thin layer to your vehicle’s exterior and interior, these coatings reduce heat absorption, keeping your car cooler and more comfortable.

But it’s not just about cars. These coatings are incredibly versatile and can be used on homes, commercial buildings, and even industrial machinery. From protecting your home’s roof and walls to boosting the efficiency of machines in high-heat environments, heat-resistant ceramic coatings provide solutions for various needs.

Benefits of Heat-Resistant Ceramic Coatings

Here’s why more people are turning to ceramic coatings to survive the heat:

- Significant Heat Reduction: Ceramic coatings reflect heat, helping reduce the surface temperature of whatever they’re applied to, whether it’s your car or your home’s roof.

- UV Protection: They block harmful UV rays, preventing surfaces from fading, cracking, or getting damaged by prolonged sun exposure.

- Durability: These coatings are built to last, offering long-term protection against scratches, corrosion, and environmental damage.

- Enhanced Appearance: Aside from protecting, they also provide a sleek, glossy finish, making your car or surfaces look even better.

- Energy Efficiency: By minimizing heat absorption, ceramic coatings can improve energy efficiency, especially in homes and vehicles, reducing your reliance on air conditioning.

Where Can You Use Heat-Resistant Ceramic Coatings?

Heat-resistant ceramic coatings offer a wide range of uses due to their versatility and ability to withstand extreme conditions. Let’s explore some of the most common applications where these coatings make a big difference.

Automotive Applications

In the automotive industry, ceramic coatings are highly valued for their ability to protect vehicle surfaces. When applied to the exterior of a car, they safeguard the paint from both heat damage and UV exposure, ensuring the vehicle maintains its shine and prevents fading over time. Ceramic coatings are also beneficial for wheels, as they resist the buildup of brake dust and endure the high temperatures generated during braking. Additionally, ceramic coatings applied to engine parts can reduce heat transfer, which enhances the overall performance of the engine by keeping critical components cooler.

Residential Uses

In residential settings, ceramic coatings provide excellent protection for homes. When applied to roofs, these coatings significantly lower heat absorption, helping to keep indoor temperatures cooler and reducing energy costs. This not only enhances comfort but also extends the lifespan of the roof by protecting it from prolonged heat exposure. Exterior walls also benefit from ceramic coatings, as they provide a shield against UV rays and heat, improving the energy efficiency of the home. Furthermore, ceramic coatings are ideal for outdoor furniture, whether metal or wood, as they prevent heat damage and help maintain the furniture’s durability and aesthetic appeal.

Industrial Applications

In industrial environments, ceramic coatings are essential for protecting machinery and equipment from harsh conditions. Factories benefit from these coatings, which help machinery resist heat and corrosion, ultimately extending the operational life of the equipment. Pipelines also gain from ceramic coatings, as they offer resistance to both heat and chemicals, reducing the frequency of maintenance and repair work. In power plants, ceramic coatings are used to protect critical components from extreme temperatures and environmental wear, ensuring that operations run efficiently without the risk of heat-induced damage.

Aerospace and Marine

The aerospace and marine industries also rely on ceramic coatings to protect their high-value assets. Aircraft and spacecraft are often coated with ceramic materials to withstand the extreme heat encountered during flight or atmospheric re-entry, safeguarding these vehicles and enhancing their durability. In the marine sector, boats and yachts benefit from ceramic coatings that protect surfaces from UV radiation and heat. This not only improves the longevity of the vessels but also helps maintain their appearance, even in harsh marine environments.

How to Apply Heat-Resistant Ceramic Coatings

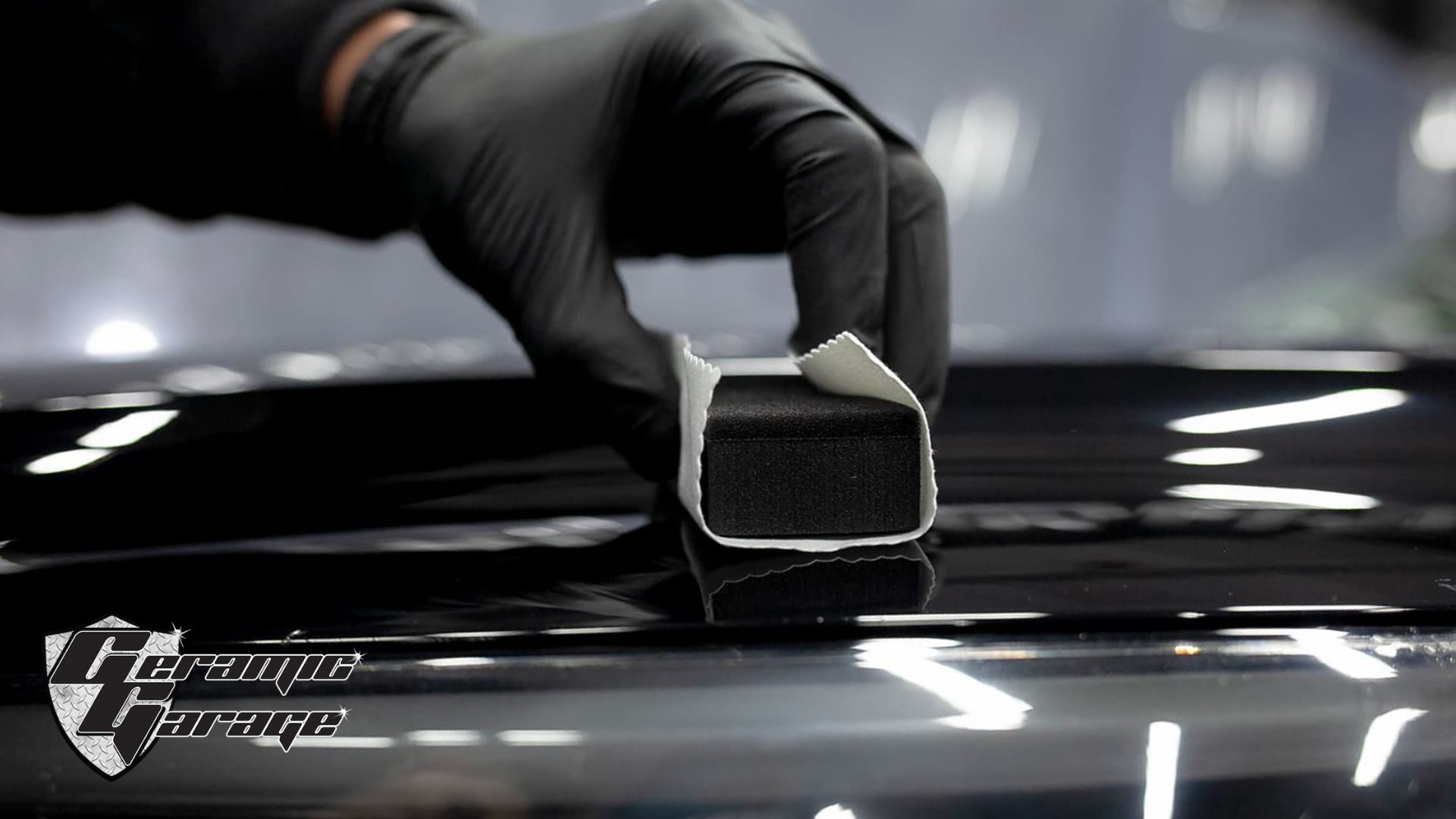

Applying ceramic coatings properly is essential to get the most out of their benefits. Here’s a brief rundown of the process:

Applying ceramic coatings properly is essential to get the most out of their benefits. Here’s a brief rundown of the process:

- Surface Preparation: Start by thoroughly cleaning the surface to remove dirt and contaminants.

- Masking: Protect areas that shouldn’t be coated, like windows or sensitive parts.

- Application: Use a brush, roller, or spray to evenly apply the coating. Work in sections for a smooth finish.

- Curing: Allow the coating to cure as per the manufacturer’s instructions. This may require letting it air dry or curing it under controlled temperatures.

- Maintenance: Regular cleaning will help extend the life of the coating. Periodically inspect and reapply if necessary.

Always remember to go to experts who can provide the best ceramic coating service. Many times, applying this type of product at home, or with inexperienced people, can cause damage to the appearance of your property, and cause you to have to spend even more money on repairs.

Maintenance & Longevity of Ceramic Coatings

One of the key reasons people love ceramic coatings is their long-lasting protection. However, a little upkeep goes a long way in ensuring they remain effective:

- Regular Cleaning: Use a mild detergent to clean the coated surface, avoiding abrasive cleaners.

- Avoid Harsh Chemicals: Steer clear of strong solvents, which can degrade the coating.

- Inspect & Reapply: Check for signs of wear and reapply the coating if needed, especially in high-heat or high-traffic areas.

Costs to Consider

Ceramic coatings can range in price depending on quality and brand. While the initial cost might be higher than traditional paints or sealants, the long-term benefits—like reduced maintenance and increased durability—make it a worthwhile investment. Keep in mind:

- Material Costs: Typically, $50 to $200 per gallon, depending on the brand.

- Application Costs: Professional application ensures better results but can add to the cost.

- Long-Term Savings: Due to their durability, ceramic coatings reduce the need for frequent reapplication or repairs, saving you money in the long run.

Final Thoughts: Beat the Heat with Ceramic Coatings

Heat-resistant ceramic coatings are more than just a trend—they’re a reliable, long-term solution to combat the harsh effects of heat. Whether you’re looking to keep your car cool, make your home more energy-efficient, or protect valuable equipment, these coatings offer numerous benefits. Don’t let the summer heat get the best of you—invest in ceramic coatings and stay cool.

Heat-resistant ceramic coatings are more than just a trend—they’re a reliable, long-term solution to combat the harsh effects of heat. Whether you’re looking to keep your car cool, make your home more energy-efficient, or protect valuable equipment, these coatings offer numerous benefits. Don’t let the summer heat get the best of you—invest in ceramic coatings and stay cool.

Ready to protect your surfaces? Contact us today to learn more about heat-resistant ceramic coatings and how they can help you beat the heat.